Your Sustainable Precious Metal Recycling Guide

Did you know that more than $60 billion worth of precious metals are discarded each year in electronic waste alone? This staggering figure underlines the critical role of precious metal recycling. It’s not just good for our economy but also for the environment. By recycling metals like gold, silver, platinum, and palladium, we cut down on pollution and save natural resources.

Firms like Dongsheng Metal Trading spearhead the movement toward greener recycling. They guarantee that valuable metals return to use instead of filling dumps. This precious metals recycling approach is key to eco-friendly recycling and sustainable practices.

Core Messages

- Over $60 billion in precious metals is disposed of in electronic waste annually.

- Precious metal recycling reduces environmental impact and conserves resources.

- Gold, silver, platinum, and palladium top the list of valuable metals.

- Green recycling methods are essential for a sustainable future.

- Firms such as Dongsheng Metal Trading focus on precious metal recovery.

Understanding Precious Metals and Their Value

Naturally scarce metallic elements called precious metals draw interest from industries and investors. Gold, silver, platinum, and palladium stand out for their distinct qualities. Notable traits are excellent conductivity, corrosion resistance, and rarity. The extraction and processing of these metals require considerable resources, underscoring the importance of recycling precious metals.

The value of precious metals is influenced by market demand and the inherent qualities of each metal. Metal recycling ensures the supply chain remains robust. It also reduces environmental impacts associated with mining activities. By thorough recycling, these metals return to their pure form. This preserves finite resources while yielding economic benefits.

Precious Metals Explained

These metals’ special traits lend themselves to diverse applications. Scarcity plus special properties drive their economic importance. Notable examples are:

- Au: Prized for its shine and tarnish-proof nature.

- Ag: Known for flexible uses and excellent conductivity.

- Pt: Celebrated for its durability and catalytic properties.

- Pd: Increasingly popular in automotive and electronic applications.

Why Recycle Precious Metals?

Recovering precious metals plays a crucial role in sustainability. It preserves resources and lessens the environmental cost of mining. Key benefits include:

- Reduction of environmental degradation caused by mining operations.

- Energy needs are far lower than mining virgin ore.

- Feeding materials back into the production loop.

- Economic upside from extracting high-value resources.

The Importance of Precious Metal Recycling

Recovering metals delivers big eco and financial wins. Emphasizing benefits helps cut environmental harm. Plus, it spurs economic development and steadiness.

Eco Advantages

The environmental benefits of recycling precious metals are significant. By reclaiming metals from discarded electronics and industrial scrap, we cut down on landfill waste. It curbs mining demand and preserves nature.

It curtails mining’s damage, like habitat loss and toxins. Focusing on recycling precious metals helps us strive for a more sustainable future.

Economic Benefits

The economic benefits of recycling are equally compelling. Recovering metals cuts production expenses. That shift enables firms to opt for recycled rather than virgin metals.

This shift creates jobs in recycling facilities and boosts market stability as demand for recycled metals grows. By leveraging these economic advantages, businesses can improve their profitability. They add to a more sustainable marketplace.

Steps in Metal Recycling

Recovering precious metals involves multiple steps for peak efficiency. It starts with collecting metals from various sources like discarded electronics, jewelry, and industrial scraps. Next comes sorting, cleaning, and testing to assess metal content and worth.

Recovery Steps

Such a methodical process ensures efficient recovery. Each step is designed to optimize the yield of precious metals. Sorting separates metals by type and purity. Cleaning strips away impurities that impede extraction. Chemical analysis pinpoints metal levels to drive technique decisions.

Recovery Methods

Advanced recycling techniques are employed to achieve high metal recovery rates. One method, thermal reduction, leverages heat to separate metals from base materials. Melting refines and aggregates metals, while wet chemical processes are used for delicate separations. Recyclers like Dongsheng Metal Trading employ these approaches to improve yields and returns.

Recyclable Precious Metals

Recycling is vital for the environment and for recovering valuable materials. Numerous precious metals lend themselves to recycling, serving both business and environment. It’s important for people and businesses to know which metals can be recycled.

Key Precious Metals

Gold, silver, and platinum are well-known precious metals. You’ll see them in rings, currency, and industrial parts. Recycling gold is common due to its high value and demand. Silver’s role in cameras, electronics, and solar energy makes its recycling vital.

Platinum, though less common, is valuable, mainly in catalytic converters.

Electronics Precious Metals

Electronics scrap contains metals ripe for recovery. Smartphones, laptops, and tablets contain rare metals like palladium and indium. These metals are a treasure trove for recycling, reducing e-waste and providing essential materials.

The need to recycle these metals is critical. Industries aim to minimize waste and efficiently recycle resources.

Who Gains from Metal Recycling?

Metal recovery underpins major sectors by supplying reclaimed resources sustainably. Device manufacturing in electronics profits hugely from recovered metals. Aerospace and medical sectors also depend on these metals for critical components. Examining industry recovery uncovers eco- and economic advantages.

Electronics Industry

The electronics industry leads in precious metal recycling due to the abundance of valuable metals in devices like smartphones and computers. Quick device turnover spawns more electronic scrap. Hence, recovering metals like gold, silver, and palladium is crucial. It preserves nature and lowers mining-driven CO₂ emissions.

Companies are increasingly focusing on recycling to meet global sustainability and waste reduction goals. This shift supports the ongoing need for resource conservation and environmental protection.

High-Tech Industries

Recycling precious metals matters for aerospace and healthcare, given their reliance on them. Alloys prized for strength and anti-corrosion make up flight and medical components. Metal recovery slashes expenses and ensures eco-compliance.

Both industries understand that responsible recycling practices help mitigate resource scarcity. And it improves operations, making metal recycling a smart green tactic.

How to Choose a Metal Recycler

Finding trustworthy precious metal recycling companies is key to recycling effectively. It’s wise to ask important questions to understand their operations. Pricing models and processes make a big difference. Reviewing offerings lets you select wisely.

Questions to Ask Recycling Companies

- Can you share your precious-metal recovery accreditations?

- Can you explain your processing methods for different metals?

- What are your recovery rates for various precious metals?

- How do you handle pricing, and what additional fees might apply?

- Can you share feedback from past customers?

Service & Price Comparison

Comparing recyclers’ offerings is crucial when choosing one. Use a table to line up these factors:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

Comparing options ensures you get top value and service. This ensures you get the most value and meet industry standards.

Precious Metal Recycling: Your Eco-Friendly Guide

Knowing recycler operations matters if you recycle metals. They handle all stages, from gathering to final refining. Such management secures peak resource use and profit.

How Recyclers Operate

Advanced workflows—assay, separation, smelting—unlock metal value. First, they gather scrap from multiple origins. Next, they employ precise methods to sort metals. Finally, they refine each batch to recover gold, silver, platinum, etc.

That workflow both boosts recovery and promotes green methods. It’s essential for long-term sustainability.

Selecting Your Ideal Recycler

When picking a recycler, several factors are important. First, look at their environmental practices. In today’s market, a commitment to sustainability is essential. Also, consider the services they offer, from basic collection to full processing.

Cost is equally important. Request estimates from multiple firms. Experts like Dongsheng Metal Trading provide industry-specific offerings. They stand out as dependable recyclers.

Pick the Right Facility

Metal recycling is a critical sector for sustainable practices and waste management. It encompasses various recycling centers, each tailored to specific metal recovery needs. Understanding these facilities improves access to recyclers and their services. This benefits both businesses and the environment.

Facility Categories

Facilities differ greatly in their focus and processes. Certain centers specialize in high-value metals; others take general scrap. Here are a few common types:

- General scrap yards handle both ferrous and non-ferrous materials.

- Specialized firms recover gold, silver, and platinum with advanced refining.

- E-waste hubs target valuable metals inside tech devices.

Facility Access Factors

Proximity to recyclers cuts logistical hurdles. Businesses must consider the logistics of transporting materials. Here are some factors that influence access:

| Factor | Description |

|---|---|

| Distance | Closer sites cut shipping costs and delays. |

| Networking | Having established relationships with local recyclers can enhance efficiency in recycling processes. |

| Service Range | Knowing each facility’s offerings guides your choice. |

In sum, selecting the right type of recycling center and ensuring convenient access can significantly enhance the efficiency of metal recycling operations.

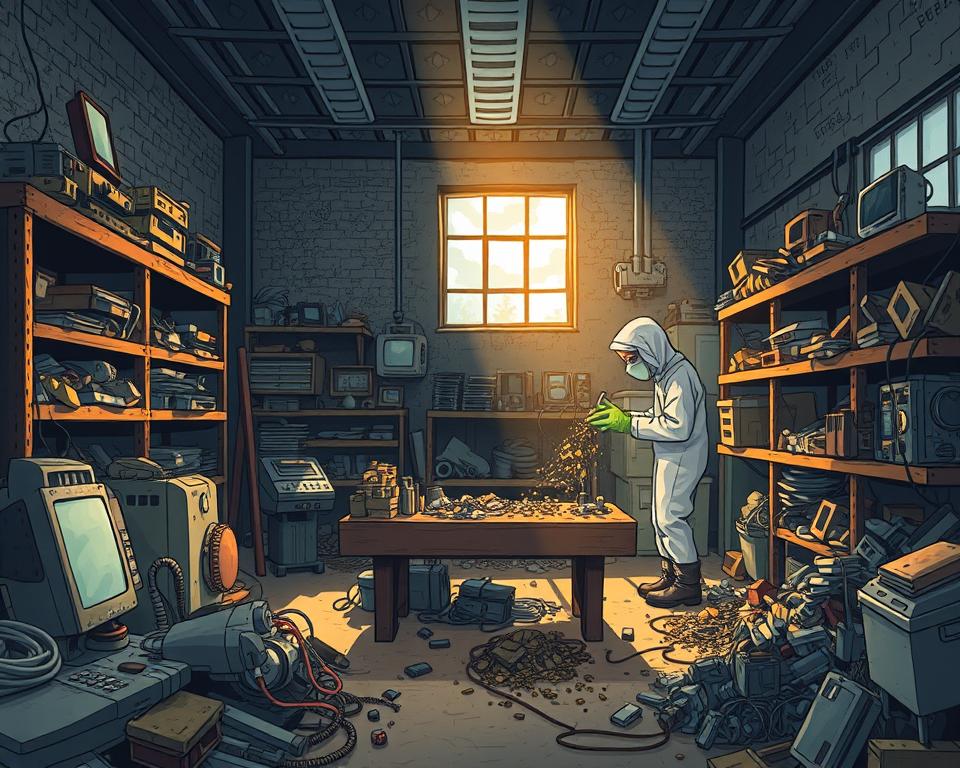

E-Waste Recycling & Metal Recovery

E-waste poses a major ecological challenge. Old gadgets hide valuable metals ripe for recovery. It shows why we should treat e-waste as treasure.

Electronic Precious Metals

Devices often contain bits of gold, silver, and palladium. These metals are found in various parts:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

From phones to TVs, electronics pack precious metals. By recycling, we retrieve and reuse these valuable elements.

Why Recycle E-Waste?

Recycling electronics protects nature and recovers resources. It trims dump loads and conserves raw materials. The benefits of recycling e-waste metals are clear:

- It lowers pollution risks tied to discarded electronics

- It curbs carbon footprints with sustainable recycling

- It fuels a circular economy by feeding materials back into manufacturing

Promoting e-waste recovery advances resource stewardship. It’s essential for the well-being of future generations.

What’s Next in Metal Recycling?

Metal recycling is evolving, spurred by tech advances and green initiatives. Facing resource limits, recyclers embrace new methods. They are embracing new methods and processes, setting the stage for the future of recycling precious metals.

Eco-Friendly Recycling Innovations

Current trends in sustainable recycling focus on reducing waste and minimizing environmental impact. Firms now use bio-packaging and low-energy methods. Such moves match worldwide green goals and nudge industries to be more eco-responsible.

Innovations in Precious Metal Recovery

Advances in recovery techniques are key to improving precious metal recycling efficiency. Robotic sorting and chemical extraction raise recovery. They boost recovery and cut environmental costs—a leap for metal recycling.

Starting a Precious Metal Recycling Venture

Starting a precious metal recycling business demands meticulous planning and a deep grasp of operational and market dynamics. Entrepreneurs must outline key steps to build a strong foundation and adhere to industry regulations. This includes conducting extensive market research and identifying target clients. Securing licenses and legal compliance is crucial for long-term viability.

Steps to Establishing a Business

Setting up a precious metal recycling venture requires several essential steps:

- Conduct market research to understand needs and rivals.

- Draft a strategy blueprint covering targets and methods.

- Purchase the right gear for your recycling operations.

- Obtain capital via loans or investors.

- Secure regulatory approvals and certifications.

- Implement a marketing strategy to draw in customers.

Regulatory & Certification Needs

Knowing regulatory requirements is vital for a recycling startup. Complying with eco-regulations keeps your business green and lawful. Key considerations include:

- Obtaining official certification from governing bodies.

- Following all levels of waste and recycling regulations.

- Training staff in safety protocols and best practices.

To Conclude

Precious metal recycling is essential for preserving natural resources and improving environmental health. It empowers all of us to reduce environmental harm from waste. That reclaimed metal cuts mining demand and spawns recycling jobs.

Metal recovery delivers both eco and economic upsides. Partnering with companies like Dongsheng Metal Trading ensures a commitment to eco-friendly practices. This collaboration strengthens the circular economy, benefiting both recyclers and consumers.

A sustainable tomorrow hinges on our joint metal-recycling efforts. Growing awareness can lead to a society that values responsible consumption and environmental care. Implementing these measures supports us today and safeguards future generations.